Get a Quote

Please send E-MAIL(qxmold@gmail.com) to me, We will reply you as soon as possible!

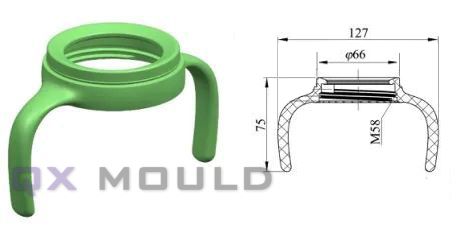

1, Structure of baby bottles cap

The structure of the water bottle cap for infants is shown in the figure, with a height of about 75 mm and two handles on the outer surface. The maximum distance between the two handles is 127 mm. The main body of the cap is a circular structure with an outer diameter of 66 mm and two internal threads on the inner surface. The specification of the internal thread is M58 mm and the length of the internal thread is 6 mm. The internal thread of the bottle cap must be demolded in unscrewing and cannot be forcibly demolded.

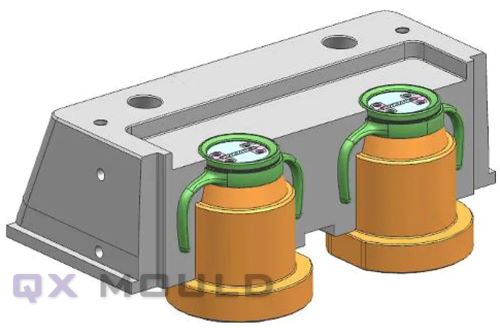

2, Mold Design

The mold adopts a 2-cavity semi hot runner design, and the external structure of the plastic part consists of 2 sliders. The internal thread of the plastic part is formed by a threaded core, and the slider is driven by an inclined guide column.

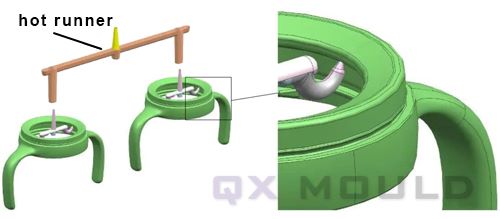

A, Gate System

Align the sprue with the parting surface between the cavity and the core in the inner hole of the molded plastic part, then open a runner on the end face of the mold core, and feed in the form of submarine gate. Each plastic part has 2 gates. This type of sprue has two advantages: 1. The gate is more concealed and does not affect the appearance of the molded plastic parts; 2. It can automatically trim the gate material and achieve fully automated production.

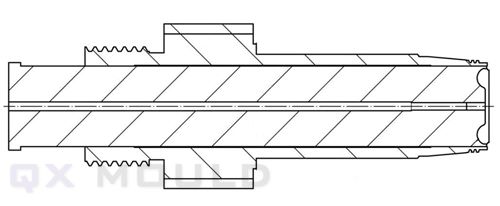

B, Core Structure

Before mold opening, the thread is driven gear by the oil cylinder to rotate the unscrewing, and then during the mold opening process, the slider separates to achieve product demolding.

C, Demoulding Structure

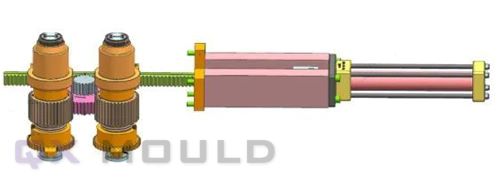

In order to enable automatic rotation of the threaded core, a transmission mechanism consisting of a hydraulic cylinder, gear rack, driven gear, threaded nut, and tapered roller bearing was designed. Install a tapered roller bearing on the bottom surface of the driving gear, with two cores driven by the same driving gear. When the threaded core rotates, under the drive of the threaded nut mechanism, the threaded core also moves along the axis direction, causing the internal thread of the molded plastic part to be demolded. In order to extend the service life of the threaded core and prevent wear, a copper sleeve is installed on the outer cylindrical surface of the threaded core.

Professional manufacturer plastic cap molds, QX Mould commit to offer our clients with precise and high quality plastic cap molds.