Get a Quote

Please send E-MAIL(qxmold@gmail.com) to me, We will reply you as soon as possible!

A flip-top cap mould, also known as flip-top closure mould, is a specialized mold used in the injection molding process to produce flip-top caps. Flip-top caps are commonly used in packaging to provide convenient access to the product inside while maintaining a secure seal when closed.

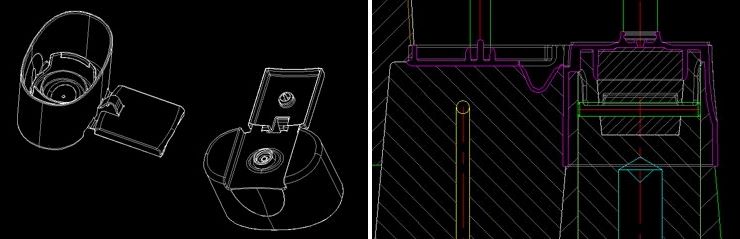

The flip-top cap mould is designed to create the desired shape and features of the cap, including the hinge mechanism that allows the cap to be opened and closed easily. The mould consists of two halves, the core and cavity, which come together to form the cap shape during the injection molding process.

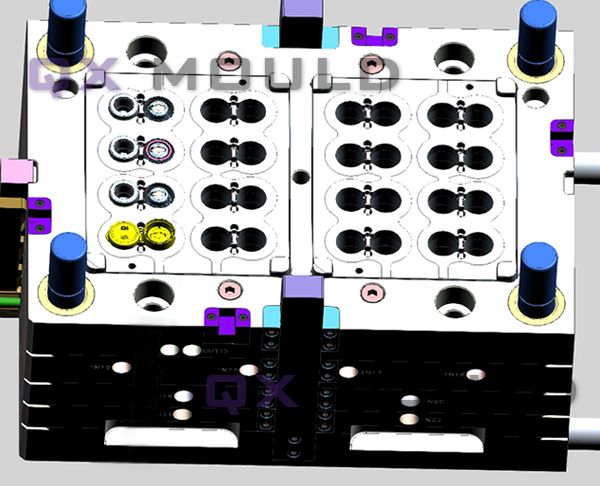

QX Mould specializes in the design and manufacturing of plastic cap mold, is one of the top flip cap mold manufacturer in China. We can offer you different kinds of 4-64 caviry flip top cap mould solutions, eg, automatic unscrewing ejection flip top cap solution, shampoo flip top cap solution, bi-injection system flip-top cap solution etc.

Flip top cap mould is very important to make the flip top cap mould well to get qualified flip top caps, is required much for different kinds of flip top caps for shampoo bottle, oil bottle, tomato sauce bottle and so on.

For a good flip top cap mould, it means we could produce good flip top caps with same quality,and the flip top cap mould could run fully automatically with high production efficiency.

For a good flip top cap, when push the flip top to close, there should have sound, when we open the flip top cap to a certain location, it could open fast by itself, this required the butterfly design and also suitable raw material for the flip top cap, when the flip top cap is closed with the bottle, it must have water proof function.

After we know the requirement for a good flip top cap, we could make the flip top cap mould accordingly.

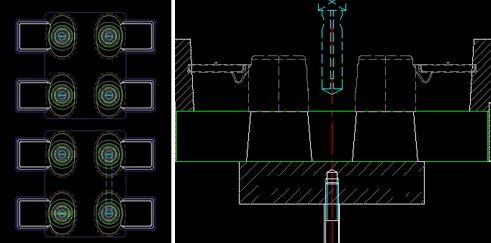

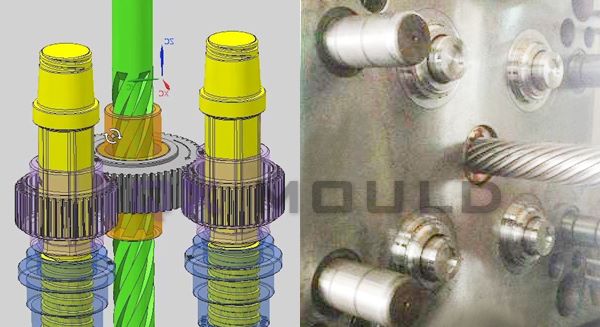

First, flip top cap mould design, the important is for injection gate location choosing, cooling system design and ejection structure design. After the mould design finished, our engineers will have a meeting to discuss about the mould movement to improve the mould structure.

Second, flip top cap mould tooling, we use stainless steel material for the core and cavity,which required twice tooling. The tooling accuracy is highly required, both for the matching and butterfly function. especially for the butterfly thickness, it will decide the flip top cap closing&opening stretch.

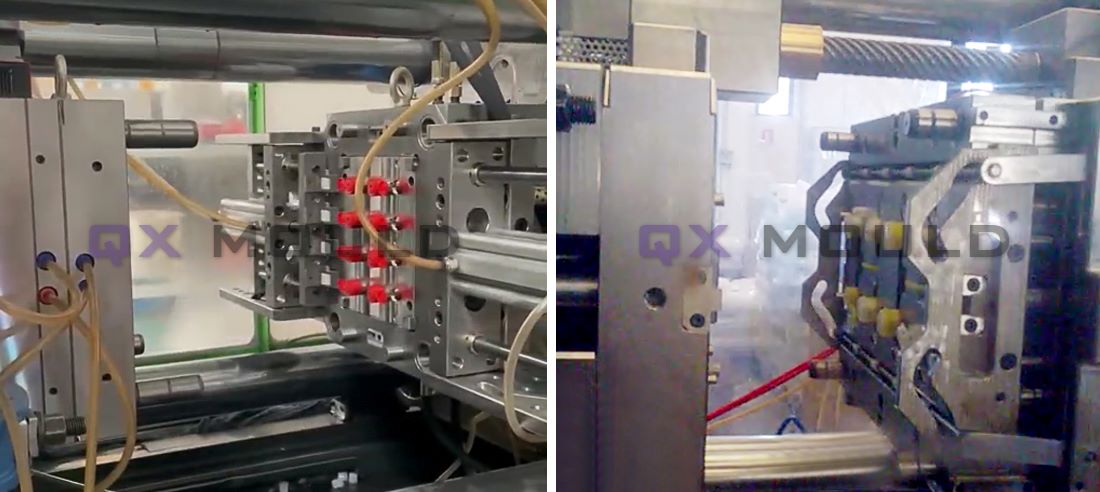

Third, flip top cap mould testing and production. The experience for machine setting is very important for this kind of mould, include the injection speed and pressure setting. Olny when we consider for all the factors, we could get a high quality flip top cap mould.

1. The flip top cap mold can be used for both cold runner or hot runner.

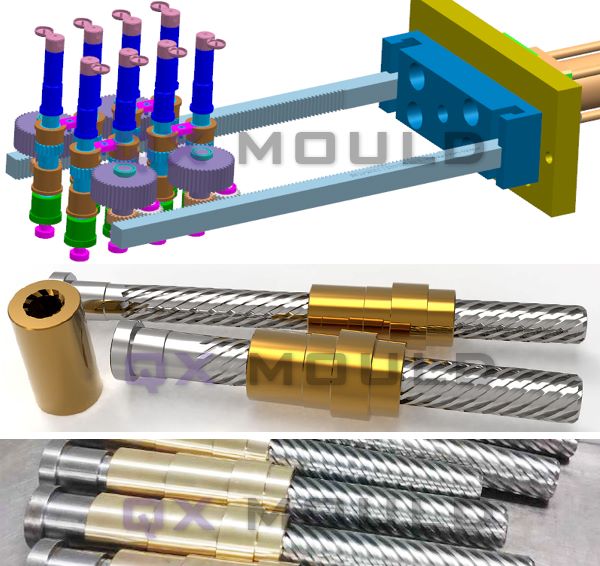

2. There are two types to ejection ssystem the flip top cap mold: Sleeve or hydraulic cylinder, hydraulic motor for unscrewing. Because to the slightly slower operating cycle of the motor, so, the new way automatic unscrewing system is the rifle bar. It is an mechanical way, when mould open, the gear system start working, so the cycle time is less.

3. The flip cap and the matching flip top cap close machine are used together to achieve flip top cap closure. There are also molds with closing in mold systems.

Relying on strict quality standards and strong technical innovation capabilities, we have established long-term cooperative relationships with many customers at home and abroad, and designed and manufactured high-quality flip top cap molds for them.

1. We attach great importance to the bow hinge design to ensure its flexibility and not easy to break.

2. We use Moldflow analysis to simulate the entire injection molding process to ensure high yield of products during mass production.

3. The hot runner system uses German heating components with excellent performance to ensure uniform melt flow and pressure in all cavities.

4. Each cavity independently controls the heat to ensure a uniform temperature.

5. Standard interchangeable mold inserts.

6. All parts are machined with high precision CNC equipment with a tolerance of less than 0.02mm.

7. High-hardness stainless steel mold core and cavity, double anti-corrosion and anti-rust, ensuring high precision and long mold life.

8. Each cavity and core has an independent cooling system that shortens the production cycle.

9. Special water pipe design eliminates water pipe leakage.

10. It is convenient to change the cavity number identification of the cavity and the core, so that the customer can quickly find and replace it correctly.

11. Our mold parts are available in DME, HASCO or other standards to make it easy for customers to find replacement parts on the market. These standards are internationally versatile and easy to purchase and easy to replace.

12. In-mold automatic flip or automatic flip can be designed according to customer requirements.

13. Mould life exceeds 2 million molds.

The flip top cap mould is a tool used in the injection molding process to create flip-top caps, which have a hinged lid that can be opened and closed for easy access to the product inside.

The number of cavities in a flip-top cap mould can vary depending on the desired production output. We can manufacture 2-32 cavity.

The materials we commonly use are Polypropylene (PP) or Polyethylene (PE).

Key considerations include the cap's dimensions, material properties, gate placement, cooling system design, and part ejection method.

There are two options: 1. The top cover and bottom are produced in different colors and then combined together. 2. The double color flip top cap mold is used in conjunction with bi-injection molding machine to complete.

There are two options: 1. After the flip top cap is produced, it is completed through flip top cap close machine; 2. Add a closed system to the flip top cap mold, and during the production process, close it inside the mold before demolding.

The life of a flip top cap mould depends on various factors, including the quality of the mould material, maintenance. A well-maintained mould can last for more than 2 million shots.

QX Mould is one of the experienced and professional manufacturer of plastic cap mould in China.