Get a Quote

Please send E-MAIL(qxmold@gmail.com) to me, We will reply you as soon as possible!

As plastic cap mold factory, we focus on producing high-quality plastic cap molds. We know that an good plastic cap mold not only needs to have good molding performance, but also needs to be able to meet the needs of different customers.

The basic functions of plastic cap mold. The plastic cap mold we produce is mainly used to manufacture various plastic bottle caps. These bottle caps are widely used in many industries. Our plastic cap mold can ensure the sealing of the bottle cap and prevent the leakage of the contents, while also ensuring the hygiene and safety of the product.

In terms of material selection, always insists on using environmentally friendly and durable materials to manufacture plastic cap molds. We know that the environmental protection of plastic products is crucial to protecting the global environment.

In terms of design, our plastic cap mold adopts advanced design concepts and technology. Our team of designers continue to explore and innovate, striving to make the plastic cap mold not only functional, but also have a beautiful appearance and a good user experience.

During the production process, has very strict quality control on plastic cap molds. We use high-precision processing equipment and testing instruments to ensure that the dimensional accuracy and surface finish of each plastic cap mold meet industry standards.

In terms of service, we provide a full range of technical support and after-sales service to ensure that customers can receive timely and effective help when using our plastic cap mold.

With the development of technology and changes in market demand, we also constantly carrying out technological innovation and product upgrades and pay close attention to industry trends and keep abreast of the latest technology trends and customer needs so that our plastic cap mold can keep pace with the times and meet the new needs of the market.

Plastic caps are favored by more and more manufacturers and people because of their plasticity, low density, high specific strength, high degree of bonding, high chemical stability and diverse appearance. The selection of plastic mould steel has a great influence on the quality of the mould. Therefore, the principle of plastic closure mould generally has the following four points:

1. Fatigue fracture performance

During the process of plastic bottle cap mould manufacturing, under the long-term effect of cyclic stress, it may cause fatigue fracture. Its form has small energy multiple impact fatigue fracture, tensile fatigue fracture and bending fatigue fracture.

The fatigue fracture properties of the mould mainly depend on its hardness, strength, toughness and the content of inclusions in the material.

2. Better high temperature performance

When the mould under a high working temperature, the hardness and strength will be lowered, resulting in early wear of the mould or plastic deformation and failure. So the mould steel should have high tempering stability to ensure high hardness and strength to hold the high temperature.

3. Resistance to cold and heat

Some plastic cap moulds are repeatedly heated and cooled during the working process, causing the cavity surface to be tensile, and with the press-induced the surface get cracking and spalling which increase the friction, impeding plastic deformation, and reducing the dimension accuracy, resulting in mould failure. Hot and cold fatigue is one of the main forms of mould failure. Therefore, for plastic bottle cap mould must have high resistance to cold and heat.

4. Corrosion resistance

Some plastic moulds will release HCI, HF and other strong aggressive gases when working due to heating which corrupt the mould surface, increase its surface roughness and aggravate wear and tear.

If want to product high-quality plastic cap mould, we must pay attention to the above points in order to ensure to get a high standard of plastic cap mould with high requirements.

1. Easy demolding: keep the plastic caps stay on the movable mold. The mold release mechanism is on the side of the movable mould. The main cores is mounted on the side of the movable mould, so that the caps are wrapped on the cores. The cavity can be placed on the fixed mold.

2. The mold structure must be simple, so that the mold is easy to be cut and processed. From the viewpoint of simplifying the mold processing, the plastic caps requiring core pulling should be avoided as much as possible in the fixed mold part.

3. Must have a smooth exhaust on cavity to ensure the cap quality. Basing on the cap appearance, the rational use of equipment and molding requirements to decide the parting surface. The plastic closures are plastic bottle caps, there is no requirements on the cover. Because the parts have lateral point-to-heart connection which need a lateral inner core pulling mechanism.

We are a professional manufacturer of various plastic jerrycan cap moulds and so on. seeking development in innovation, seizing opportunities in competition, and provide customers with high-quality plastic cap moulds.

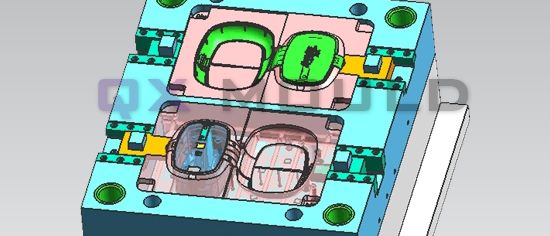

Product Name: Wet Wipes Tissue Cap Mould

Plastic Material: PP / PE etc.

Steel of Cavity & Core: S136, 2083, 2344 etc.

Steel of Mold Base: S50C; P20.

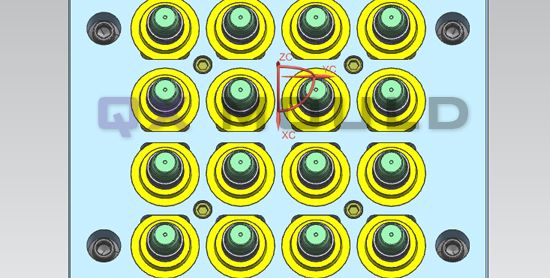

No. of Cavity: multi.

Core pulling or Ejection system: Depends on the Product.

Surface Finish: Depends on the product.

Mold Life: More than 2 million shots.

Runner system: Hot Runner.

Delivery time: For First trial: 45 ~ 60 days after mold drawings approved.

Packing: Wooden Case.

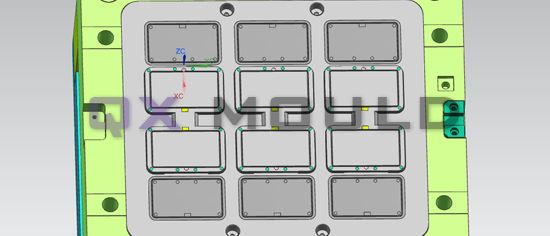

Product Name: Wide-mouth jar Cap Mould

Plastic Material: PP / PE etc.

Steel of Cavity & Core: S136, 2083, 2344 etc.

Steel of Mold Base: S50C; P20.

No. of Cavity: multi.

Core pulling or Ejection system: Stripper plate.

Surface Finish: Depends on the product.

Mold Life: More than 2 million shots.

Runner system: Cold runner / Hot Runner.

Delivery time: For First trial: 45 ~ 60 days after mold drawings approved.

Packing: Wooden Case.

The planning of plastic cap mold needs to be based on the shape, accuracy, size, technical requirements of plastic caps. The following aspects should be considered in mold planning:

1. Number of cavities and placement method: As the plastic cap is produced in large quantities as a packaging container, considering the mold locking force, injection volume of the existing injection molding machine, and the accuracy and economic factors of the bottle cap, it is determined mold cavities number.

2. Pouring system planning: According to the layout of plastic caps, the mold is planned into hot runner or cold runner. hot runner the point gate is selected, the gate is set in the center of the top of the plastic part. Cold runner the mold is planned three plates or submarine gate.

3. Cooling system planning: The mold temperature conditioning system of plastic cap mold directly affects the quality and production power of products. In order to improve the cooling power of the cavity, the cooling circuit is selected. The diameter of fixed mold cooling water channel is φ 12mm, connected with the hose outside the mold to form circulating cooling.

Follow Up Production Schedule and Promote On-time Delivery

We accept your 2D drawings, 3D drawing or samples. After analysis, start designing and providing mould drawing.

During the production stage, we will send you regular updates of process status and process photos.

After the mold installation is completed, mold trial, and send you samples, if there is any problem, it will be adjusted.

When the right result will be reached, mold will be shipped. and provide after-sales service.