Get a Quote

Please send E-MAIL(qxmold@gmail.com) to me, We will reply you as soon as possible!

The bottle cap mold is typically made of high-quality steel and is designed with precision to ensure that each cap produced is identical in size, shape, and quality. Bottle caps form an essential part of the manufacturing process in the packaging industry. The molds are used to create the caps that seal and protect a variety of beverages, foods, and drug packaging etc.

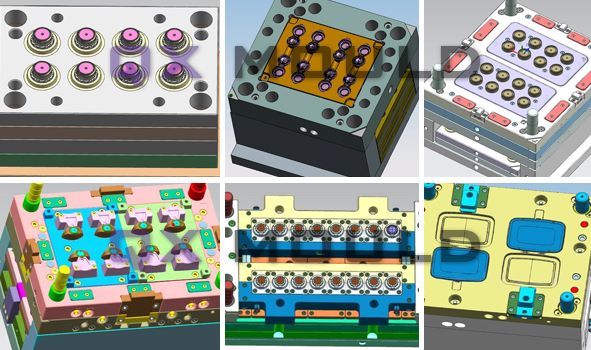

Flip-top caps are made of plastic and have a locking mechanism to open and close them. QX Mould has been manufacturing cold runner and hot runner flip top cap mould for many years. We has accumulated rich experience flip top cap molds from 4 cavity to 48 cavities, like shampoo flip top cap mold, lubricant oil flip top cap mold, condiment flip top cap mold etc.

Plastic cap mould, also known as a plastic closure mould, is a specialized mold used in the manufacturing process of plastic caps or closures. QX Mould has accumulated rich experience in various plastic cap molds from 2 cavity to 72 cavities, like pull up spout cap mould, wet wipes cap mould, urine cup cap mold, jerrycan cap mould etc.

With over 10 years of technology and production experience of PET Preform Mould, produces more than 100 sets multi-cavity PET Preform moulds per year, ranging from 8 to 96 cavities. For many years have made the Preform Mould of QX Mould more durable, easier maintenance and more efficient production.

Professional manufacturer plastic cap molds, QX Mould commit to offer our clients with precise and high quality plastic cap molds.

Our design team and engineering staff have years of combined experience, reasonable mould structure, excellent cooling system, shorten the production cycle.

Strictly purchase the appointed steels requested by the customer,and achieve the promised steel hardness Imported steel can provide steel inspection report.

The latest equipment for quality and productivity provides our skilled craftsmen the accuracy and productivity to efficiently deliver on our quality promise.

A, Analyze the feasibility of designing mold products to ensure the correctness of their product drawings before design. The work to be done after product analysis is to analyze what structure the product adopts and sort the products.

B, According to the product development plan, determine the dimensions of the templates in the drawings, including fixed plates, discharge plates, punches, inserts, etc. It is beneficial to prepare materials directly in the product development plan for drawing its diagram. After the material preparation is completed, fully enter the drawing of the mold diagram, and create a new one in the material preparation diagram to draw various parts. When drawing the mold diagram, attention should be paid to every production point, such as fitter marks, cutting, lines, etc. Different processing techniques have complete layers, which is very beneficial for wire cutting and drawing management.

1. Multi-cavities: mature technology from 4 cavities to 32 cavities. Simplified hot runners are reliable and low cost.

2. High efficiency: a simplified dispensing hot runner with pin point hot runner, no waste material, a cycle time of 5 seconds.

3. Long mould life: the cavity is made of high quality mould steel, heat treatment HRC52. The mould guide pin and bush adopt oil-free lubrication method, no pollution; the cores parts can reach HRC60. The mould life can reach to three million shots.

QX Mould is one of the experienced and professional manufacturer of plastic cap mould in China.

We can now make two types of cap molds, injection cap molds and compression bottle cap molds. The injection molding process is achieved by using injection molding machines and injection molds to shape the caps; The compression bottle caps is formed by compression molding machine and the mold.

When comparing injection molding and compression molding, it’s clear that while compression molding offers advantages such as fast color changes and lower energy consumption, injection molding is a more versatile and efficient process overall. Injection molding provides design freedom and production flexibility to meet the needs of most beverage brands and converters.

Injection cap mould cavity and core of the plastic bottle cap mold is made of high-quality mold steel, and the guide sleeve of the mold guide column is lubricated without oil, which has the strong advantage of no pollution and a service life of up to 3 million shots.

Each cavity of the plastic bottle cap mold is self-locking independently, which can ensure the concentricity of the mold. The excellent cooling system can achieve the high efficiency of constant temperature water cooling, and the shear free gate can reduce the labor intensity of workers.

According to the layout of the plastic parts, the mold is planned into three plates and the point gate is selected. The gate is set at the center of the top of the plastic parts. The point gate can significantly improve the shear rate of the melt, greatly reduce the melt viscosity, and is conducive to mold filling. Moreover, as a packaging container, the plastic parts have a high demand for appearance quality, and the residual traces of the point gate are small, which can ensure the surface quality of the plastic parts; During demoulding, the gate is actively pulled off, facilitating the automation of product production process, improving production power and increasing economic benefits.

Yes, we have successfully manufacture double color 5 gallon bottle cap mould and some two-color flip top cap moulds

Cap injection molding process enables each finished one to achieve high precision, uniformity in size, and shape, and high surface finishing. In this process, the plastic particles are heated in a metal hopper to the point that they become very soft and pliable. It is possible to add color to the plastic at this stage. The softened plastic is then injected under high pressure into a complex structural steel or aluminum mold. Here the glue is filled into the cavities in the mold and cooled enough to harden. Finally, the mold will open for bottle cap removal.

<p>While selecting a Bottle Cap Mould, it is crucial to choose a company with a proven track record in the production of quality caps. A bottle cap mould maker must also have access to effective materials and highly skilled technicians. QX Mould is a manufacturer of cap molds, It's your best choice.</p>